|

Getting your Trinity Audio player ready...

|

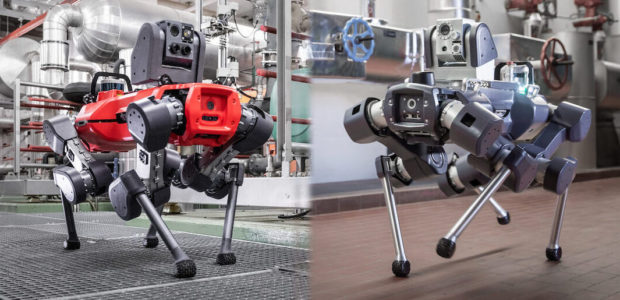

Collaboration between information technology leader Accenture, robot solutions provider ANYbotics and, data and digital twin platform provider Cognite, has propelled robotics into a new era. This is the era of mobile, autonomous and intelligent robots. Robots that enable a new level of hyper-automation. Autonomous robot systems are performing an increasing range of tasks across industries and making independent decisions with a high degree of autonomy. Inspection walks in complex plants in the Oil and Gas, Chemicals and Basic Materials industries, for example, are becoming the domain of robots. Mobile, autonomous, intelligent, legged robots such as ANYmal.

Robot Autonomy, Mobility and Collecting Data through various Perception Technologies, are just the First Steps

ANYmal is engineered for optimum use in complex industrial areas. With the help of its sensors, ANYmal manoeuvres on four legs on uneven ground, climbing stairs, avoiding obstacles and accessing inspection points from several directions. Even adverse weather conditions don’t disrupt ANYmal, because its body is 100% waterproof and dustproof. ANYmal collects data and information through various perception technologies. The fact that ANYmal remembers positions exactly enables long-term observations of critical points with an accuracy that humans could hardly achieve. For example, by photographing a point at the same distance and angle every day for weeks. ANYmal can accept numbers, document visual anomalies in images, measure and record discrepancies in temperature, distance, and noises.

ANYmal independently scrutinizes complex industrial sites and performs autonomous inspection tasks. These tasks include visual inspections and automated readouts of analog instruments such as gauges, liquid level, and lever positions, advanced thermography and vibration analysis of equipment, as well as 3D scanning of the infrastructure. In addition, ANYmal can be equipped with gas detection sensors to monitor the presence of a range of gases.

Data Integration is key to Effective End-to-End Robotic Inspection Solutions

ANYmal integrates as an end-to-end solution through its software APIs with asset management software and digital twin platforms such as Cognite. Data is evaluated with the help of artificial intelligence (AI) and forwarded to maintenance teams with recommendations for action. Industrial connectivity is the central foundation of the modern smart plant and is revolutionising industrial workflows as is demonstrated at Accenture Industry X Innovation Center.

Only with the right interfaces can data be easily transferred from the robot to the data platform and from there passed on to other IT systems. For this, smooth integration of hardware and software, targeted use of AI and optimal processes are essential. This part of the cooperation lies with Accenture. The analysis of data collected by ANYmal that reveals futures problems, for which maintenance tickets are automatically issued, for example. Conversely, maintenance and repair systems can automatically dispatch ANYmal on inspection or maintenance missions without involving humans. Accenture’s integrated data platform makes this possible.

Hyper-automation is made possible by rapid technological advances in hardware and software, which is how robots operate autonomously within a large radius of actions. The algorithms and artificial intelligence (AI) systems required for cross-functional data processing are now accessible and cost effective. Furthermore, in systems optimally designed for cross-functional cooperation, the merging of human and machine competencies and skills create a comprehensive collaborative intelligence.

There is more to hyper-automation than a large radius of action and a high level of autonomy – robots are more effective and efficient when they are closely integrated into existing systems and take on additional tasks. This is where Cognite’s data and digital twin platform comes into play: The company specializes in linking data between IT and OT systems and using AI to recognize a wide variety of connections. ANYmal, for example, transfers data it gathers from its inspection missions to this ‘knowledge’ platform where the AI analyses all numbers, images, or noises, and alerts maintenance teams regarding abnormalities. This AI groundwork allows people to immediately focus on pertinent issues, such as detailed images of rust spots, liquid leaks or data on pipe deformation. As a result, the use of robots and AI enables humans to optimize operations, maintenance and repairs.

New Techniques in Digitization make Jobs in Maintenance and Repair more Interesting

Autonomous robots relieve people of dangerous, dirty and dull tasks. Robots are rapidly improving their ability to act and make decisions, i.e., usable intelligence through interaction with data platforms connected to companies’ IT and/or OT systems. In the future, however, powerful, AI-supported robots will only pay off if the users themselves acquire the skills to create the models required for new fields of application. From the user’s perspective, such skills acquisition projects should take two important aspects into account.

Firstly, change management is essential so that everyone directly involved understands the advantages of using robots and the changed processes and actively helps to shape the introduction. Robots should relieve people so that they can concentrate on more valuable tasks than, for example, carrying out monotonous tours. The shortage of skilled workers poses challenges for numerous industries.

Second, successful human-robot collaboration requires basic knowledge and experience in dealing with robots and AI systems. This training and the application of new techniques in digitization make jobs in maintenance and repair more interesting and upgrade them at the same time. Thanks to graphical user interfaces, however, there is no fear that employees will have to be retrained as computer scientists and AI experts.